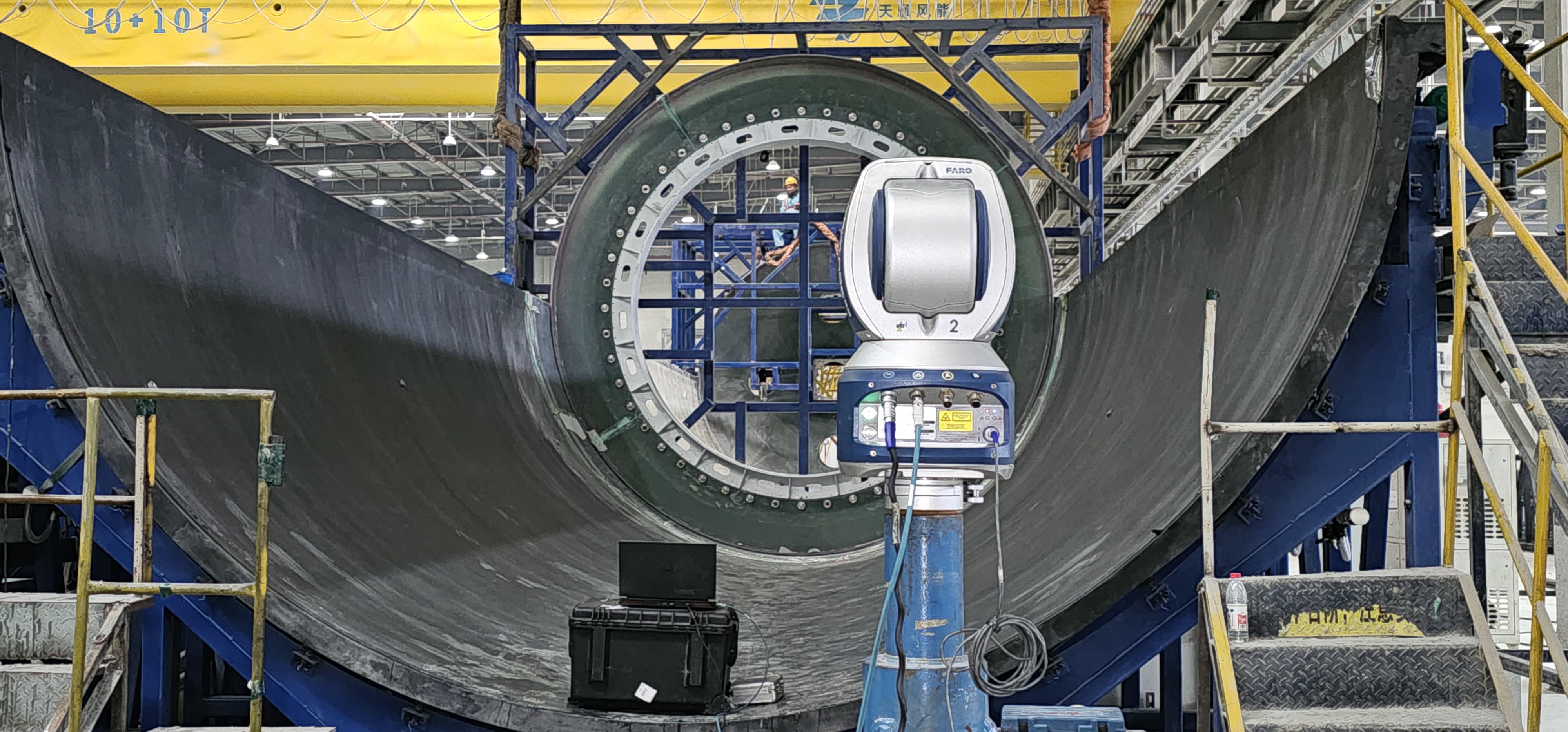

In the global power generation industry, leading power station operators and service providers employ Portable Coordinate Measuring Machines (PCMMs) for blank part marking to ensure a zero - rejection rate. Subsequently, Laser Trackers are utilized to conduct final measurements and complete on - site installation work.

Since its introduction to this field, the PCMM has been rapidly adopted and highly commended. A senior heavy - electromechanical engineer remarked, "Your solution has resolved our long - standing issues. The electromechanical components and steam turbine cylinders, weighing nearly 100 tons, previously required three to four workpiece turn - overs for manual marking. The adjustments after each turn - over accounted for 80% of the total workload and kept the bridge crane occupied. Now, with the coordinate measuring machine, the marking process can be completed in one step, significantly enhancing both efficiency and precision. This is truly outstanding."